The US has one of the safest food supplies in the world, yet we almost always hear reports about a new crop of foodborne illnesses. These reports make national news and are eminently shareable on social media - not the kind of publicity any food producer wants.

To help prevent these incidents, Congress passed the Food Safety Modernization Act (FSMA) in 2011 which is now starting to be enforced. This new set of codes amended the Food, Drug, & Cosmetic Act of 1931. A big part of this act is the focus away from responding to food contamination and moving toward putting greater measures into preventing the contamination from happening in the first place. The act gives wider regulatory authority to the FDA in terms of inspection and recalls.

Of note is Section 103 - "Hazard Analysis and Risk Based Preventative Controls" - which highlights ways in which the food producer is responsible to take a pro-active approach to preventing food contamination. This section states that "the owner, operator, or agent in charge of a facility shall... evaluate the hazards that could affect food manufactured, processed, packed, or held by such facility, identify and implement preventive controls to significantly minimize or prevent the occurrence of such hazards and provide assurances that such food is not adulterated...monitor the performance of those controls, and maintain records of this monitoring as a matter of routine practice."

highlights ways in which the food producer is responsible to take a pro-active approach to preventing food contamination. This section states that "the owner, operator, or agent in charge of a facility shall... evaluate the hazards that could affect food manufactured, processed, packed, or held by such facility, identify and implement preventive controls to significantly minimize or prevent the occurrence of such hazards and provide assurances that such food is not adulterated...monitor the performance of those controls, and maintain records of this monitoring as a matter of routine practice."

Additionally, the FDA goes into more detail about hazard analysis in supporting materials. They mention that a good analysis must consider "known or reasonably foreseeable biological, chemical, and physical hazards" that can "occur naturally, unintentionally introduced, or intentionally introduced for economic gain."

The bottom line is that you need to be covering all of your bases when it comes to being proactive in preventing food contamination. Adding preventative measures like replacing existing cord drops and cordsets with anti-microbial wiring devices and electrical cable is an inexpensive step down the path to FSMA compliance.

Do you have questions about anti-microbial electrical products? Contact us or download our Food & Beverage Solutions Guide!

Tag(s):

Industry Solutions

John Nouse

John has been involved in the power distribution, power quality, and lighting world for 20 years, working with maintenance/facility teams and engineers to solve problems and promote safety in retail, commercial and industrial spaces.

More from the blog

View All Posts

Workplace Safety

5 min read

| March 14, 2017

How Can You Prevent a Food Recall and Save Money?

Read More

Antimicrobial

2 min read

| February 6, 2020

What is FSMA and Why is it Important? Food Safety Modernization Act

Read More

Workplace Safety

1 min read

| June 10, 2019

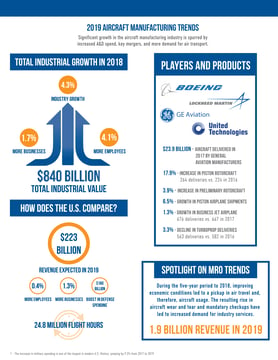

Infographic: 2019 Aircraft Manufacturing and Maintenance Trends from Ericson

Read MoreSubscribe to blog updates

Stay up-to-date on what's happening at this blog and get additional content about the benefits of subscribing.