Keeping personnel safe on the job should be the top priority of any business. In most industries this is a relatively simple task, but for many - like construction, oil and gas refining, shipbuilding, aircraft MRO and others - the job of keeping everyone safe at work is more of a challenge. That's why we have things like the Occupational Safety and Health Administration (OSHA) and the National Fire Prevention Agency's National Electric Code (NEC) to keep everyone on a level (and safe) playing field.

In the latest iteration of the NEC, there were a few subtle changes that made a big impact on temporary job sites and projects that use temporary power distribution. One of those changes is in regard to using ground-fault circuit-interrupters (GFCIs) for personnel protection.

Article 590.6(1) - GFCI Protection for Temporary Installations

The addition of one sentence changed a lot about what can be done on a job site or project that uses temporary power. It is mandated (and has been for years) that GFCI protection shall be provided for all 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not part of permanent wiring. With the change to article 590.6(1) of the 2017 NEC, it is now permissible to use "listed cord sets or devices incorporating listed ground-fault circuit-interrupter protection for personnel."

The addition of one sentence changed a lot about what can be done on a job site or project that uses temporary power. It is mandated (and has been for years) that GFCI protection shall be provided for all 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not part of permanent wiring. With the change to article 590.6(1) of the 2017 NEC, it is now permissible to use "listed cord sets or devices incorporating listed ground-fault circuit-interrupter protection for personnel."

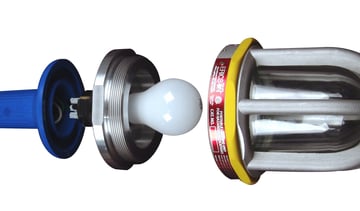

That means, you may now use Nationally Recognized Testing Laboratory (NRTL) listed inline GFCI cord sets and devices like Ericson's industrial-grade XG2 series and be within code. XG2 series GFCIs are exceptionally designed, NEMA 6P rated, built for years of service, and are a great addition to any job site.

590.6(3) Assured Equipment Grounding Conductor Program

While not a change in the latest code update, article 590.6(3) works hand-in-hand with previous articles in this section to provide protection to personnel. This article describes the correct procedures for implementing a mandatory Assured Equipment Grounding Conductor Program for all "cord sets, receptacles that are not part of the permanent wiring of the building or structure, and cord-and-plug-connected equipment." An AEGCP states that you must conduct two tests to all previously stated equipment - ground continuity and that equipment grounding conductor is connected to its proper terminal.

An easy way to stay on top of your AEGCP is to use visual diagnostic wiring devices with easy-to-see LEDs that will alert you when there is something amiss with your equipment wiring. Ericson's SmartMonitor devices check 7 conditions including ground continuity, reverse polarity, hot on ground, and open neutral conditions and will save both time and money when implemented as part of your AEGCP.

An easy way to stay on top of your AEGCP is to use visual diagnostic wiring devices with easy-to-see LEDs that will alert you when there is something amiss with your equipment wiring. Ericson's SmartMonitor devices check 7 conditions including ground continuity, reverse polarity, hot on ground, and open neutral conditions and will save both time and money when implemented as part of your AEGCP.

Codes and regulations change over the years but one thing remains the same - Ericson will be there for you. For over 100 years, we've been manufacturing the best electrical safety products on the market with an eye towards durability, ease-of-use, and total cost of ownership. Learn more about what we do at ericson.com.

Jeff Angle

Jeff is the Chief engineer, PE & Six Sigma Blackbelt with 25 years in the biz. His degree is in Electrical Engineering from University of Akron and has an extensive background in product development, UL regulatory compliance & ISO9001 quality assurance.

More from the blog

View All Posts

Workplace Safety

2 min read

| August 30, 2016

Why Your Electrical Safety Provider Should Have Engineering Expertise

Read More

Workplace Safety

2 min read

| March 16, 2020

What is explosion proof or hazardous location lighting?

Read More

Certifications and Regulations

1 min read

| May 9, 2017

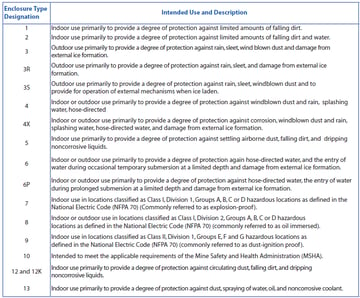

What is NEMA, and What are its Enclosure Designations?

Read MoreSubscribe to blog updates

Stay up-to-date on what's happening at this blog and get additional content about the benefits of subscribing.