June 12, 2024

Protecting Workers and Cords From Harm, Safety Through Compliance

Written by: Brian Earl

The leading cause of electrical shock injury in temporary power applications is portable extension cords. Protecting workers and cords from accidents through cord set safety is of paramount importance anywhere portable extension cords are used.

Following Compliance rules is key to safety. Electrical (NEC and NFPA) and Worker Safety Codes (OSHA) outline several ways to ensure cord safety – here are a few explained and distilled in brief.

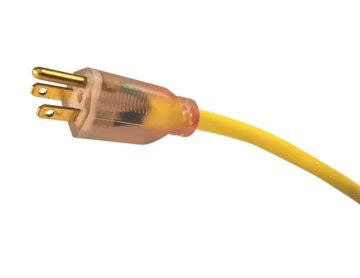

Cord safety compliance ensures that cords used on jobsites are safe and use proper technology to ensure safety. To ensure cord safety, NEC 590 and OSHA 1926 outline cord inspection practices under the Assured Equipment Grounding Conductor Program. These codes ensure that from the start of the job and intervals throughout, temporary power application is safe. The code requires a program be set up to inspect and assess portable cords to ensure continuity of all cord conductors and cords are free from damage. Cords are evaluated before they are placed into services and at 3-month intervals, or when a cord is repaired, to ensure safety. The cords are then marked to show the cord has been inspected. There are products, Ericson Smart Monitor Products, which check the cord and connection continuously to ensure the cord is not damaged and assembled cords have proper connections and continuity. The plugs and connectors have a light that shows a safe condition. Green means the circuit is safe, red shows the cord or connector continuity needs inspection.

Safety through technology – portable cords strewn about the jobsite are, by nature, subject to damage. Using in-line GFCI protection with UL943-5th edition ensures that if an upstream neutral connection is lost or a conductor is severed, the circuit is opened, and power disconnected from the cord preventing shock. This also applies if a damaged tool or cord is subjected to submersion in water, the cord is opened as well – similar to the way GFCI (Ground Fault Circuit Interrupters) area required by code in kitchens, bathroom, basements and outdoor all areas with high potential for water intrusion. Ensure any GFCI you use is of the latest technology, 943-5th Edition, to ensure self-testing technology is employed. NFPA 70e states that, in any portable power application, portable in-line GFCI protection must be used.

Protection from Cord Damage – portable cords and hoses laying on the floor, ground or deck of a site are susceptible to damage from vehicles, people, sharp corners or falling objects. NEC590 requires cable and hose protection. These units typically come in 3’ lengths and connect end -to-end where damage is certain to happen, known and unknown traffic patterns across floors, around corners or where damage is predicted, near charging areas for scissor lifts, for example.

Ericson offers a range of Jobsite Cord Solutions to ensure safety and code compliance for workers.

Brian Earl

Hailing from Minnesota originally, Brian began his secondary education at the University of Minnesota with his undergraduate work and his MBA in Management at University of Michigan, focusing on strategic marketing and market planning. He has an extensive background in developing and leading a variety of marketing,...

More from the blog

View All Posts

Strain Relief and Cord Grips

7 min read

| March 14, 2024

The Importance of Wire Mesh Strain Relief for Portable Cords

Read More

Wiring Devices

7 min read

| December 5, 2024

Selecting Commercial and Industrial Wiring Device for your Application

Read More

Workplace Safety

17 min read

| August 20, 2024

Industrial Grade Job site Lighting Solutions for Confined Spaces

Read MoreSubscribe to blog updates

Stay up-to-date on what's happening at this blog and get additional content about the benefits of subscribing.