August 20, 2024

Industrial Grade Job site Lighting Solutions for Confined Spaces

Written by: Brian Earl

Industrial Task and Area Lighting applications present unique challenges due to their diverse range of product solutions, ranging from standard task lighting to specialized equipment for confined spaces and hazardous environments.

This blog will discuss applications in atmospheres defined as damp locations and confined space. Next month’s blog will discuss harsh and hazardous lighting applications.

When you hear a person talking about working in a "confined space," that does not necessarily mean working in tight quarters. "Confined space entry" is a term that has a set of safety requirements for personnel working in those defined spaces.

For an area to be classified as a confined space according to the code, it must satisfy all three of the following criteria:

- Large enough for personnel to perform work.

- Limited openings for entry and exit

- Not intended for continuous human occupancy

Examples of these types of spaces include tanks, vessels, utility holes, silos, storage bins, hoppers, vaults, and pits.

But "confined space" is not a one-size-fits-all term. Depending on the conditions within the space, there are further definitions and, therefore, requirements, which must be adhered to.

To better understand this below we have highlighted examples of confined spaces and the requirements that define them:

-Permit-Required - A confined space requires the company safety department to permit the space and inform all parties of the date and times of maintenance routines to ensure that if workers occupy the space all equipment off locked out and tagged. These spaces include areas that:

- Contain or has the potential to contain a hazardous atmosphere.

- Contain a material that has the potential for engulfing the entrant.

- Has an internal configuration such that a person could become entangled in equipment, trapped, or asphyxiated by inwardly converging walls or by a floor which slopes.

- Contains any other recognized serious safety or health hazard/s

-Non-Permit Required - a confined space that does not contain or have the potential of atmospheric hazards that might cause death or serious physical harm, does not require permitting.

-No-Entry Confined Space - Space restricted from entry.

-Hazardous Atmospheres - An atmosphere which poses a danger to both the location/equipment and workers. Hazardous atmospheres defined as:

- Flammable – known as enriched oxygen atmospheres, vaporization of flammable liquids, chemical reactions, and concentration of combustible dust or absorption of chemicals from inner surfaces of the confined space.

- Toxic - entire spectrum of gases, vapors, and air-borne dusts. Some examples of toxic atmospheres are manufacturing processes such as charcoal, product storage such as removal of a substance from a tank or maintenance work such as welding in a confined space.

- Irritant/Corrosive - these types of atmospheric hazard have primary and secondary groups.

- Primary irritants exert no systemic toxic effects because the products formed by them on tissues of the respiratory tract are non-irritant and other irritant effects are so violent as to obscure any systemic toxic action. Examples are chlorine, ozone, and hydrochloric acid.

- Secondary irritants may produce systemic toxic effects in addition to surface irritation. In most cases, the worker is not aware of any increase in the exposure to these hazardous toxic substances.

- Asphyxiating – Deficiency in the proper amount of Oxygen. Reduction of oxygen in a confined space may be the result of either consumption or displacement.

- Ventilation - OSHA does not define the number of air exchanges required (some states offer requirements for this), but the typical rule is to have at least five complete air exchanges per hour.

For more information about confined spaces and the requirements surrounding them, visit the OSHA website.

Now that we have outlined challenging areas that require task lighting, there are specific requirements for lighting products used in these spaces.

Confined and hazardous spaces are dangerous for all sorts of reasons, without the risk of electrocution added to the list. Task lighting used in these spaces needs to meet specific atmospheric requirements and contain any internal explosion as well. For example, lighting used in confined spaces with or without hazardous vapors must either be low voltage; defined here as 12-volt AC or include GFCI protection.

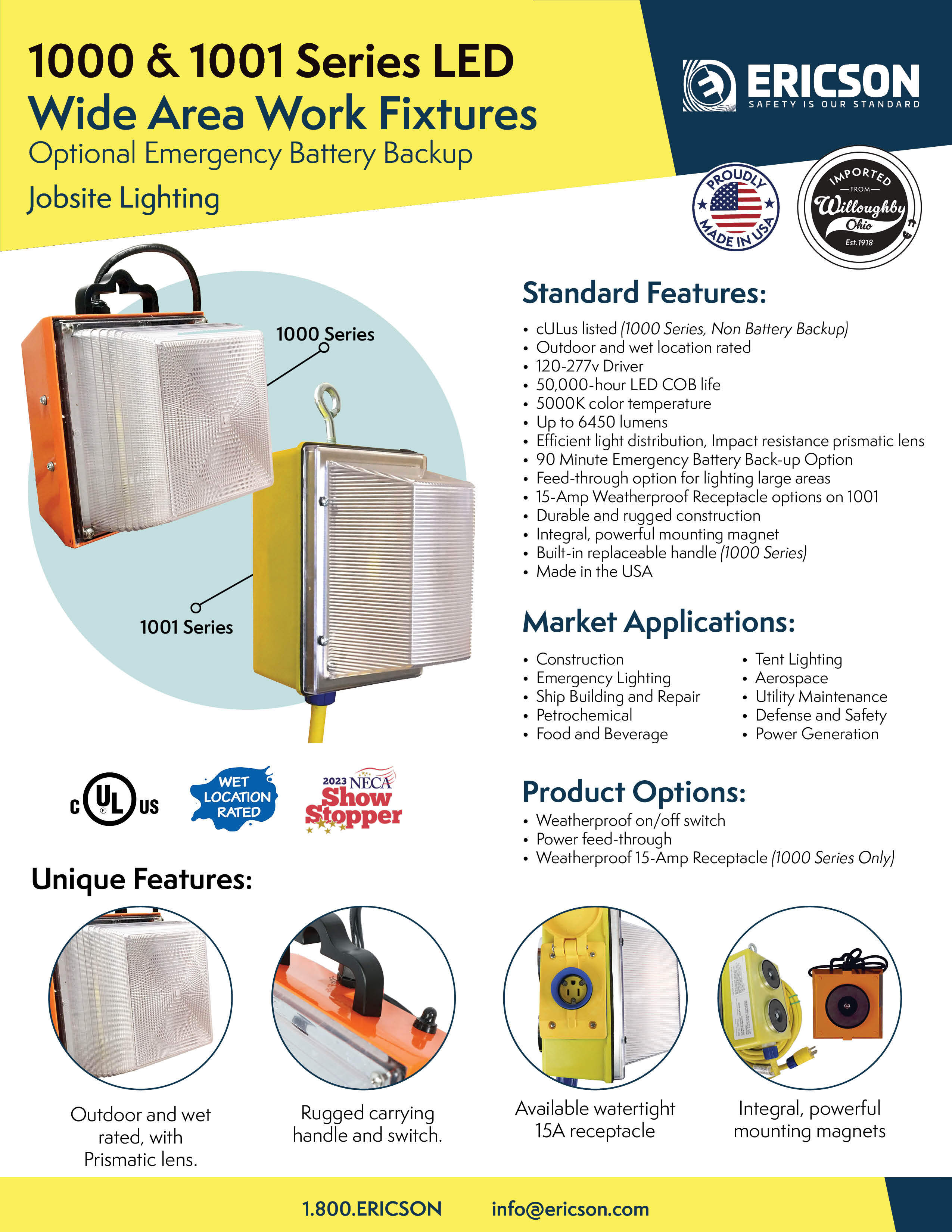

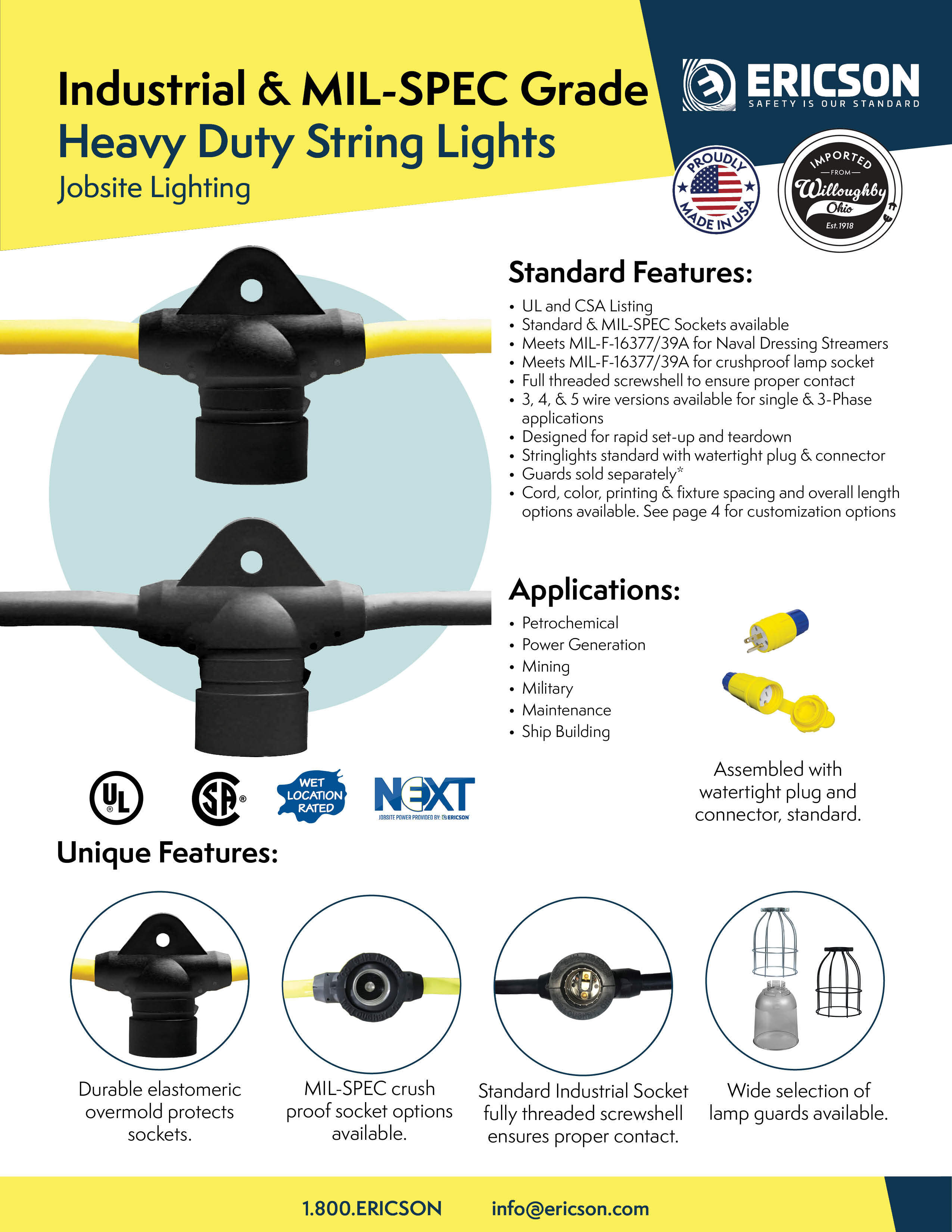

Additional considerations for safety departments include ensuring safe egress for workers in the event of power and lighting failures. Utilizing lighting products equipped with a 90-minute battery backup can ensure that workers are able to exit hazardous and confined spaces securely. Ericson offers an extensive range of work lights tailored to withstand atmospheric vapors and the challenges of harsh work environments.

Since 1918 Ericson has been a leader in lighting for demanding and hazardous locations. Click on any of the product references below and download our Confined Space Solutions Guide to learn more about how Ericson can make your job site safer.

Brian Earl

Hailing from Minnesota originally, Brian began his secondary education at the University of Minnesota with his undergraduate work and his MBA in Management at University of Michigan, focusing on strategic marketing and market planning. He has an extensive background in developing and leading a variety of marketing,...

More from the blog

View All Posts

Workplace Safety

11 min read

| September 26, 2024

Choosing the Best Lighting for Harsh and Hazardous Environments

Read More

Portable Power

7 min read

| March 21, 2024

Ericson Nonmetallic Box Solutions Update

Read More

New Product Launch

7 min read

| March 21, 2024

Power Distribution Unit Product Update

Read MoreSubscribe to blog updates

Stay up-to-date on what's happening at this blog and get additional content about the benefits of subscribing.