July 24, 2017

Reviewing Classified Hazardous Locations for Refinery Turnarounds

Written by: Greg Brown

Planning of temporary power distribution and job site lighting, and the implementation

thereof, are key components of refinery turnaround maintenance operations. Below we will introduce the hazards of refinery turnarounds and provide a brief overview of hazardous location classifications which are necessary to complete the temporary power and lighting planning prior to your next turnaround project.

SAFETY FOCUSED –

REVIEW OF HAZARDOUS LOCATION CLASSIFICATIONS

As turnarounds are an essential reality for refineries, a key to these maintenance activities is the safety of personnel, equipment, facility and the environment. Activities such as welding, drilling, sanding and cutting all require adequate lighting, and all of which require electricity to function. Additionally, there are many times when the electrical distribution, lighting and tools must be capable of operating in different types of hazardous locations.

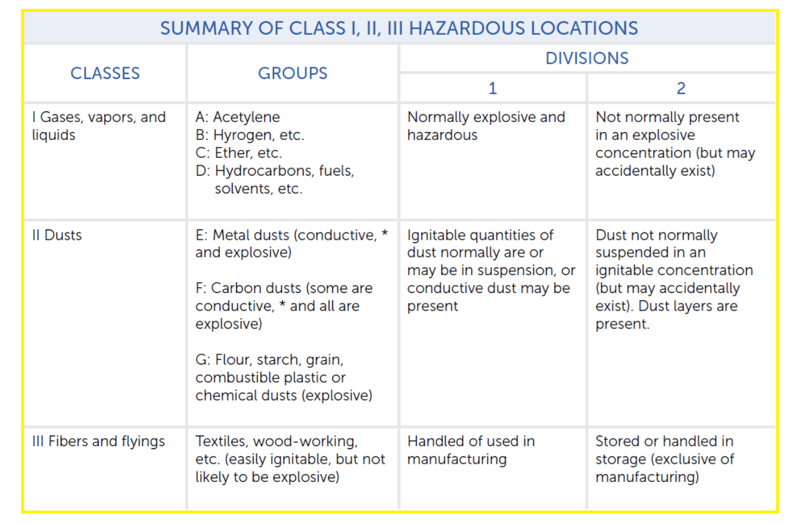

The National Electric Code (NEC) classifies hazardous locations in three ways by Type, Condition and Nature. The Types of hazardous conditions include gas and vapor, dust, fibers and flyings. To simplify the identification of these conditions they have been categorized as Class I, Class II and Class III respectively.

Two kinds of hazardous conditions are identified by the NEC, namely Division 1 which signifies a normal condition (i.e. normal or regular exposure) and Division 2 which is abnormal (i.e. occasional, infrequent exposure). The Nature of the hazardous substance is further defined as Groups A, B, C, and D in Class I locations, and, in Class II locations: Groups E, F, and G. These groups represent the ignition temperature of the substance, the explosion pressure, and other flammable characteristics.

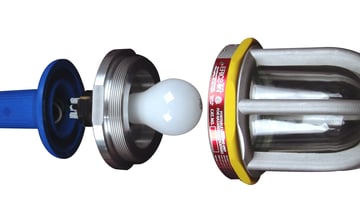

All temporary power distribution and lighting used in classified hazardous locations must be designed to function in these environments, and are only available from a select group of manufacturers. Safety is the primary concern; therefore, it is no longer an accepted practice for contractors to build electrical panels with the hope that catastrophic failure points will be avoided.

CLASS I EQUIPMENT MUST HAVE THE FOLLOWING CHARACTERISTICS:

Explosion-Proof

• Strength

• Durability

• Capable of withstanding the internal strain of an explosion

Well Established Flame Path

• Controlled escape path for exploding gases

• Gases are cooled off and flames extinguished

• Several types exist including threaded and ground surface

Special Fittings and Seals

• Prohibits hot gases from traveling through the conduit system

• Prohibits flammable dusts from entering dust-ignition-proof enclosures

• Prohibits ignition in other areas of the closed system

At Ericson, we understand that turnaround activities are inherently dangerous; therefore, management must incorporate a safe well planned execution strategy. Understanding your hazardous location classifications is a critical aspect of this strategy.

Greg Brown

Greg Brown is an Applications Engineer.

More from the blog

View All Posts

Workplace Safety

2 min read

| March 16, 2020

What is explosion proof or hazardous location lighting?

Read More

Certifications and Regulations

6 min read

| December 14, 2021

Safe & Compliant Jobsite Lighting

Read More

New Product Launch

4 min read

| March 21, 2024

Upgraded Harsh & Hazardous Lighting Solutions

Read MoreSubscribe to blog updates

Stay up-to-date on what's happening at this blog and get additional content about the benefits of subscribing.